Multiple distributor system

multiFlow improves production stability and increases tool life

Complex injection moulds require the precise controlling of heating circuits, for which an appropriate number of temperature control units are used. The many devices obstruct the space around the machine and require complex hose guides. multiFlow by Regloplas AG offers a solution in which one device controls up to 16 heating circuits at once. This saves space and costs, improves production stability and prolongs the tool life of the moulds.

The plastic processor qtec Kunststofftechnik GmbH Quedlinburg (DE) is known for customer-specific designed injection-moulded parts from Thermoplast as well as completely assembled systems made of plastic and metal. These products are the basis for high-quality end products in the automotive industry, for electronics suppliers or in fluid engineering. PPS, a glass fibre reinforced, linear polyphenylene sulphide compound, is used for the production of impellers for cooling water pumps. This plastic exhibits very good mechanical properties up to more than 200 °C and has exceptional chemical stability against virtually all solvents, many acids and lyes. The minimal water absorption and good dimensional stability make PPS the ideal material for quality products. PPS is processed at qtec on the latest injection moulding machines in the hightemperature range. Mould wall temperatures of 140 °C to 160 °C must be adhered to, requiring an exact temperature regulation within the tolerance range of +/- 5 °C to attain short cooling times.

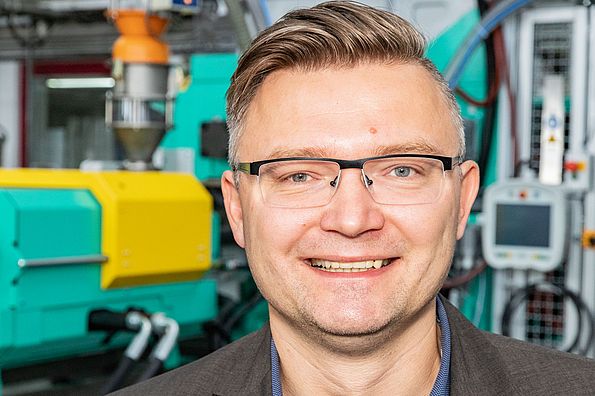

Regloplas and their sales partner FIMRO from Halberstadt (DE) have been reliable partners of qtec for many years when it comes to precise temperature regulation of injection moulds. “The very precise temperature control, the reliable operation and the simple maintenance of Regloplas units continues to convince us when it comes to the manufacture of our high-quality plastic products. Added to this is the excellent service and the exceptional advice from FIMRO which guarantees us a high standard of production safety,” explains Marco Dudda, Team Leader of injection moulding at qtec.

For the first time in 2015, qtec gained experience with the multiple distribution system multiFlow by Regloplas for the production of a particularly challenging part. Rather than several devices for eight heating circuits, two Regloplas P160M pressurised water temperature control units, each with a multiFlow distribution system, have been connected to the mould. “With regard to the impellers, for qtec, it primarily concerned improving the process monitoring of temperature control circuits. To do this, we wanted to move away from series connection and towards parallel distribution. This caused the flow rates of individual circuits to be demonstrably better measured and controlled,” explains Matthias Zörkler, sales advisor at FIMRO GmbH who sells the Regloplas devices in Germany.

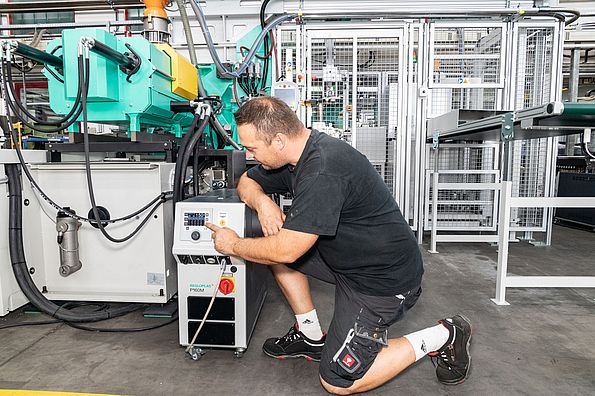

Each Regloplas P160M temperature control unit has one water supply to the relevant multiFlow with eight channels. From there, eight short temperature control hoses lead directly to the mould connections of the injection mould in parallel. “After just a short time, we recognised that the compact multiFlow distribution system offers many advantages for the factory. With just one temperature control unit, four heating circuits are separately supplied in parallel and the flow rate is regulated with the tightest of tolerances. We do not need to insert several devices, which saves time and cable-hose assemblies. It is also easier to control the heating circuits since each circuit is monitored individually. In the centre of the RT100 front panel, it is immediately easy to see where there is a blockage or error in the mould,” explains Marco Dudda.

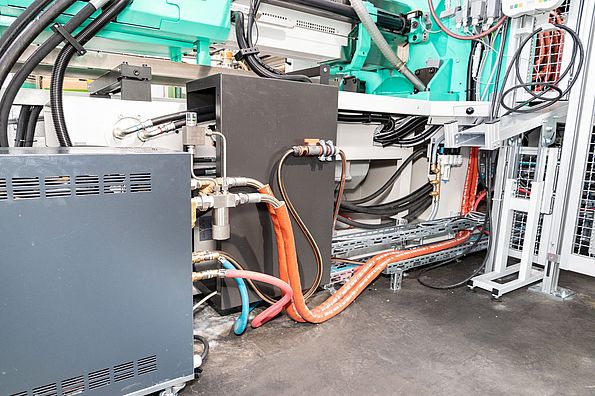

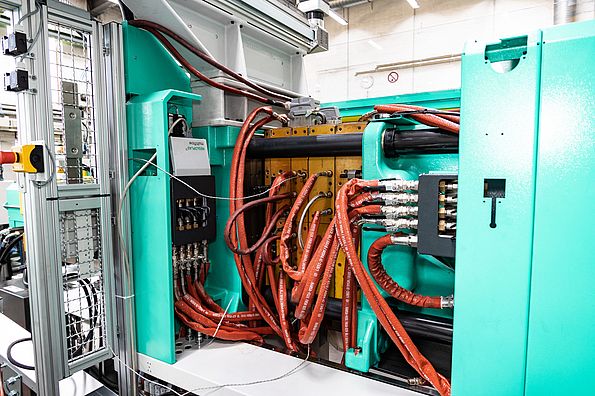

Four precisely controlled and monitored temperature control circuits lead from each multiFlow (seen here on the moving mould element) to the injection mould.

For the latest investment by qtec in Quedlinburg, an Arburg Allrounder 579S, the installation of the multiFlow technology was planned from the start and technically coordinated with the machine manufacturer. Arburg moved the position of the plugs and connections to the outside, enabling the placement of both multiFlow distributors to the fixed and movable clamping plate. The temperature control hoses could thus be configured to be as short and space-saving as possible. “With both of the 4-part multiFlow distributors, the tight construction space in the injection moulding machine was perfectly utilised. This creates space all around the system since only two, rather than several, temperature control units are in operation,” explains Matthias Zörkler.

The multiFlow multiple distribution system by Regloplas offers a large range of functions and many configuration versions. In the mechanical version, which is also used at qtec, the flow rate is set using hand valves to suit each channel of the mould. The automatic version is populated with motor-driven flow valves that are continuously regulated via the RT100 control of the temperature control unit.

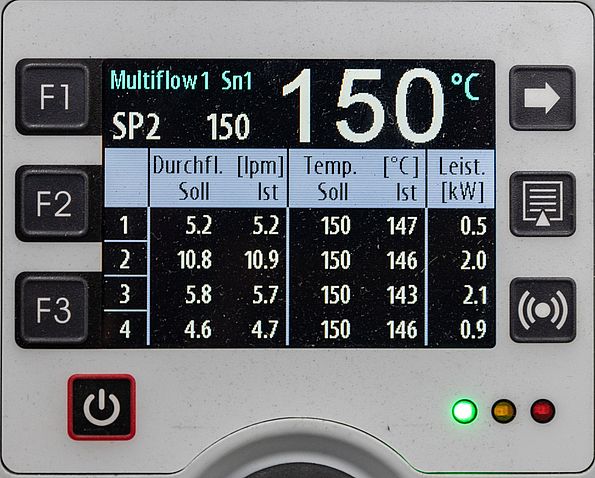

The multiFlow system controls 4 - 16 temperature control circuits in parallel using individual parameters. The flow rate, temperature and power of each circuit is clearly displayed on the RT100 controls. The precise flow measurement of the multiFlow allows the very tight temperature tolerances of +/- 5 °C to be precisely adhered to during the processing of the PPS plastics at qtec. This ensures that the process cycle is continuously carried out at the highest quality level.

It also has another advantage that Matthias Zörkler explains: “Each mould design is subject to certain tolerances based on temperature differences. The closer the temperature tolerances can be adhered to, the less is the thermal stress on the injection moulds. This provides production stability and prolongs the tool life of the expensive moulds!"

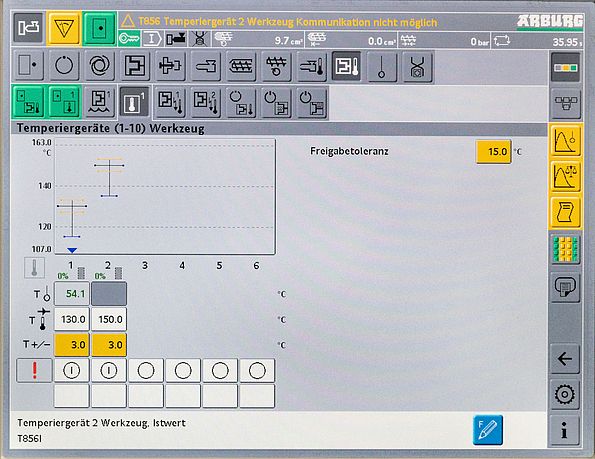

To ensure that the system operator has an overview of all production data on the main controls of the injection moulding machine, the Arburg control reproduces the parameters of the Regloplas temperature control units on its own touchscreen. From there, the operator carries out settings on the temperature control units, further improving the monitoring of the processes and reducing the chance of wastage in production.

The multiFlow units (left image) are placed directly on the injection mould. To do this, the electrical connections (right-hand image) are moved to the outside.

The controller RT100 of the temperature control unit Regloplas P160M shows all parameters of the four connected temperature control circuits at a glance. The data can likewise be displayed and influenced via the Arburg controls (outlined in red).

At qtec, systems managers Matthias Koehler and Marco Dudda are in agreement that multiFlow by Regloplas offers a great deal of advantages to production. “Since we are using fewer devices and therefore also require fewer feed lines, the total investment becomes more economical and there is less heat radiation from the feed lines. The combination of pump performance, heating performance and multiFlow technology halves the form's heating up time from approx. 3 hours to 1.5 hours. Furthermore, it is significantly easier to monitor and control the heating circuits with multiFlow than with individual devices placed around the machine. Adhering to the tolerance range of +/- 5 °C at mould wall temperatures of 140 °C to 160 °C gives us greater certainty and flexibility in production. We were able to calculate after just a short amount of time that the availability of the system increased and there was a reduction in production delays. Also, thanks to reduced downtimes, the process stability improved overall,” explained Marco Dudda on the improvements achieved with multiFlow by Regloplas.

With the multiFlow multiple distribution system, Regloplas has a product in its portfolio that has proven its value in the production process of high-quality injection moulded components at qtec. For the plastic experts from Quedlinburg, it is already clear today that they will choose this clever solution from Regloplas AG from St. Gallen, Switzerland, for future new acquisitions and modifications.

Marco Dudda, qtec Quedlinburg:

„multiFlow by Regloplas has increased the availability of our system and is in many ways a winner in the production of high-quality injection moulding components.”

The Regloplas P160M temperature control unit can be placed anywhere and is easy to operate.

Regloplas AG

Regloplas AG is a family-owned company that has specialised in the development and production of intelligent temperature control systems with Swiss quality for more than 55 years. These ensure maximum process stability through exact control accuracy in the temperature ranges. Regloplas AG offers its customers worldwide complete temperature control solutions for highly sophisticated manufacturing processes and is thus a market leader.

https://www.regloplas.com

For more information please contact your local representative via the contact form.