Savings potential in dynamic temperature control

A new temperature-control concept from Regloplas AG reduces the undesirable mixing of cold and hot heat-transfer media by separating them and temporarily storing them cyclically. This makes the energy-intensive variotherm temperature control more efficient and cost effective.

Dynamic temperature control, with its cyclic change between high and low-temperature heat-transfer media is gaining in importance for both thermoset and thermoplastic injection-molded parts. With the application of this process, which has become widely known as variotherm temperature control, plastic resin systems benefit from a reduced curing time. In injection molding, a brief conformal heating of the mold ensures a highquality surface and complete molding of complex microstructures; the immediate cooling also permits rapid demolding and consequently a high throughput.

However, the rapid temperature change in variotherm temperature control entails a higher energy consumption: the rapid sequence in which hot and cold heat-transfer media are introduced into the injection mold leads to a mixing of the two media, and consequently a significant loss in energy efficiency.

With such alternating temperature control, two temperature control units are provided – one at a high and one at a low temperature level. An internal fluid tank in the temperature-control units serves as a heat store, and buffers the temperature fluctuations that rapidly occur. A hangeover unit connects the temperature control units to the mold, through which two media at preset temperatures flow alternately. The high temperature of the heating unit Tu improves the reproduction of the surface as well as the pressure transmission, and thereby reduces the pressure& demand during mold filling and during application of the holding pressure, which in turn has a positive effect on part warpage. The low temperature of the cooling unit Tl ensures that the plastic is rapidly cooled to the demolding temperature.

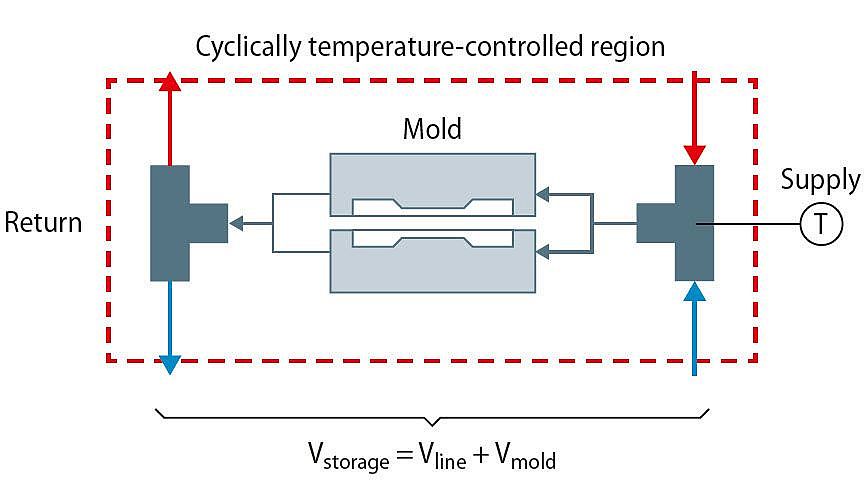

During changeover from heating to cooling, the entire heat-transfer medium is cyclically pushed out of the lines and the mold (Fig. 1) of the heating unit, into the cooling unit and back again; the two heat-transfer media are mixed. In the first case, when the heated medium passes into the cooling unit, this reinforces the loading of the cooling network, i. e., the temperature in the cooling circuit increases. In the second case, when the cooler medium passes into the heating unit, it must be heated back to the target temperature. This costs energy and takes time. In the worst case, the medium no longer reaches the target temperatures, and the operator must turn to a more powerful temperature control unit.

the mold (T stands for the temperature measurement position) (source: IET)

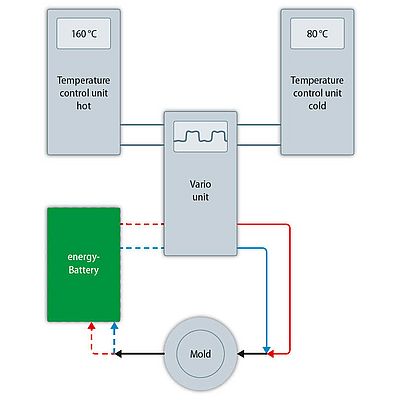

An innovation of Regloplas AG, St. Gallen, Switzerland, temporarily stores the cold and heat-transfer media in a so-called energyBattery. At the correct time, which the changeover unit (type: Vario) automatically recognizes, the heat-transfer medium is pushed to the temperature-control unit that is at the same temperature level. The mixing of the cold and hot heat-transfer media is thus prevented (Fig. 2).

The separation and intermediate storage of the heat-transfer media has a benefit that is independent of the circumstances of the particular mold and the selected operating conditions. The average savings potential can be determined to a first approximation via the heat-transfer medium volume Vstorage in cubic meters (m3), the operating temperatures in Kelvin (K) and the cycle time in seconds (s). Based on the average material characteristics, the mixing of the heat transfer media results in a lost average performance in watts of:

Pcapacity = Vstorage * p *cp *(Tu - T1) / tcycle time

For the heat transfer, water, in the temperature range between 100 and 200 °C, an average density p of 920kg/m3 and an average heat capacity cp of 4320J/(kg·K) can be assumed. The greatest cost savings thus result theoretically for applications with large storage volume, large temperature differences and short cycles.

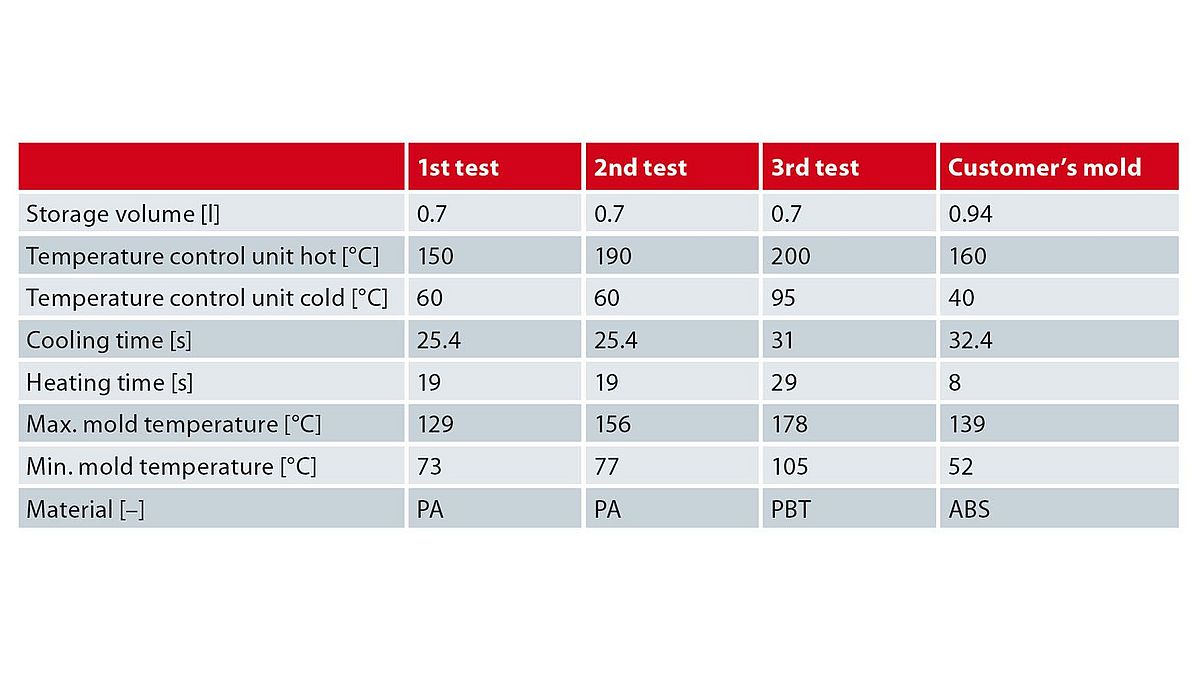

In a joint project, scientists at the Institut für Werkstofftechnik und Kunststoffverarbeitung (IWK) and at the Institut für Energietechnik (IET) at the Hochschule für Technik Rapperswil determined the energy saving empirically in a range of experiments. They used a customer’s mold and a mold especially produced for the purpose (manufacturer: IWK, Rapperswil, Switzerland). The molds were operated with two water temperature control units (type: P200M, manufacturer: Regloplas). The study was conducted on three different plastics that come into consideration for variotherm temperature control, and are used by customers (Table 1). The operating points used were determined under realistic conditions of production with large hourly production rates.

The energy saving was measured after the machine had reached the steady state, via the required electrical power demand of the heating unit. The other parameters and settings on the temperature control units were not changed in the tests with and without the energyBattery.

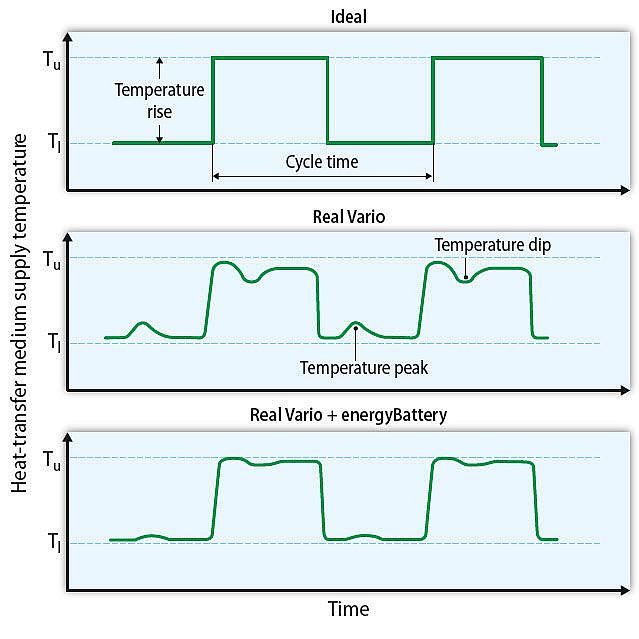

In operation, differences in the feed temperature profile were apparent (Fig. 3). With the temporary store, the mold is subject to smaller temperature fluctuations. With respect to a short cycle time, this leads to an approximation to the ideal temperature control curve. The dips and peaks in the supply temperature are effectively reduced. This effects an optimum and rapid temperature control and has less thermal load on the mold.

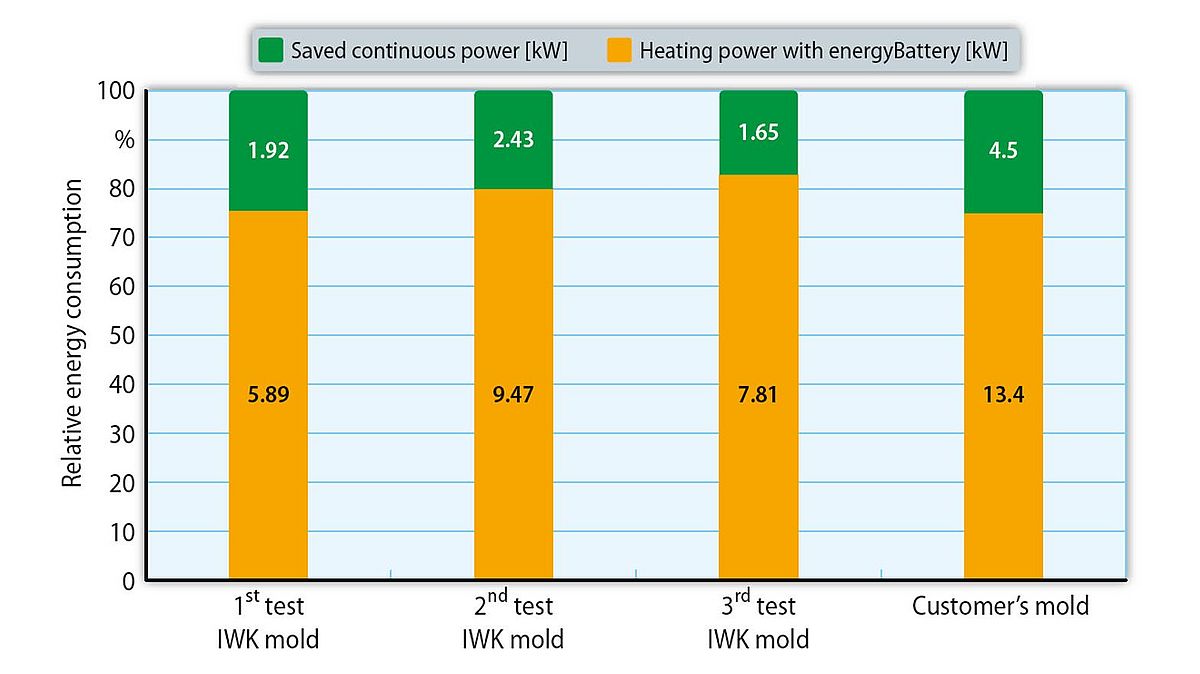

In all tests with an energyBattery, considerable energy savings of approx. 20 % were measured with uniform part quality (Fig. 4). The energy saving potential in the customer mold was particularly conspicuous. Due to the series connection of the temperature control circuits, the mold has a long feed, and consequently used a large fluid volume for temperature control.

Extrapolated to one-shift operation of 2000 machine hours per year, the customer’s mold, assuming an industrial electricity price of approx. 17 euro cents per kWh [1], achieves a saving of EUR 0.765/hour or EUR 1530/annum. The saved performance in the cooling unit is strongly dependent on the cooling technology used and the operating conditions of the cooling water circuit. The savings potential in the cooling circuit was therefore not examined in greater detail.

The energyBattery demonstrably improves the efficiency of temperature control on the tested molds with uniformly high quality of the injection molded parts. Due to the more efficient operation, the temperature-control system can be better regulated to the desired temperature and there is less thermal load on the cooling water circuit. In particular cases, the operator can achieve shorter cycle times because of the higher average supply temperatures.

The development took place in collaboration with the IET Institut für Energietechnik at the HSR Hochschule für Technik Rapperswil and was funded by the KTI/Innosuisse.

Images and Content: © Kunstoffe