P180S eMold

The efficient, energy-saving and compact pressurized-water temperature control unit with unmatched connectivity. Designed for plastic injection molding and industrial applications up to 180 °C

- Automatic energy-saving modes (Delta-T, flow control, pressure control)

- Most efficient, high-performance pump with variable pump speed (IE4, synchronous motor)

- RT200 controller with modern touch interface

- Maximum functionality and features included

- Unmatched RT200-connectivity

- Access through LAN, WLAN, web browser (HTML 5), TeamViewer

- OPC UA interface standard on all units

- Additional interface integrated

- New ESK-cooling with variable capacity

- Separated Cooling circuit (Low calcification, long lifetime)

- Compact, robust, and field-proven design

Technical specifications

more

less

Heat transfer medium

Outlet temperature

Heating capacity at 400V

Cooling capacity

Pump capacity/Type

Water

180

°C

8

kW

170

°C

90

kW

PM23H

50

l/min

1.4

kW

Technical data

more

less

| Outlet temperature | ||

| max. | °C | 180 |

| Heat transfer medium | Water | |

| Filling quantity | l | 1.0 |

| Expansion volume | l | - |

| Heating capacity at 400V | kW | 8 |

| Cooling capacity | kW | 90 |

| Cooler | 2ESK | |

| at outlet temperature | °C | 170 |

| at cooling water temperature | °C | 20 |

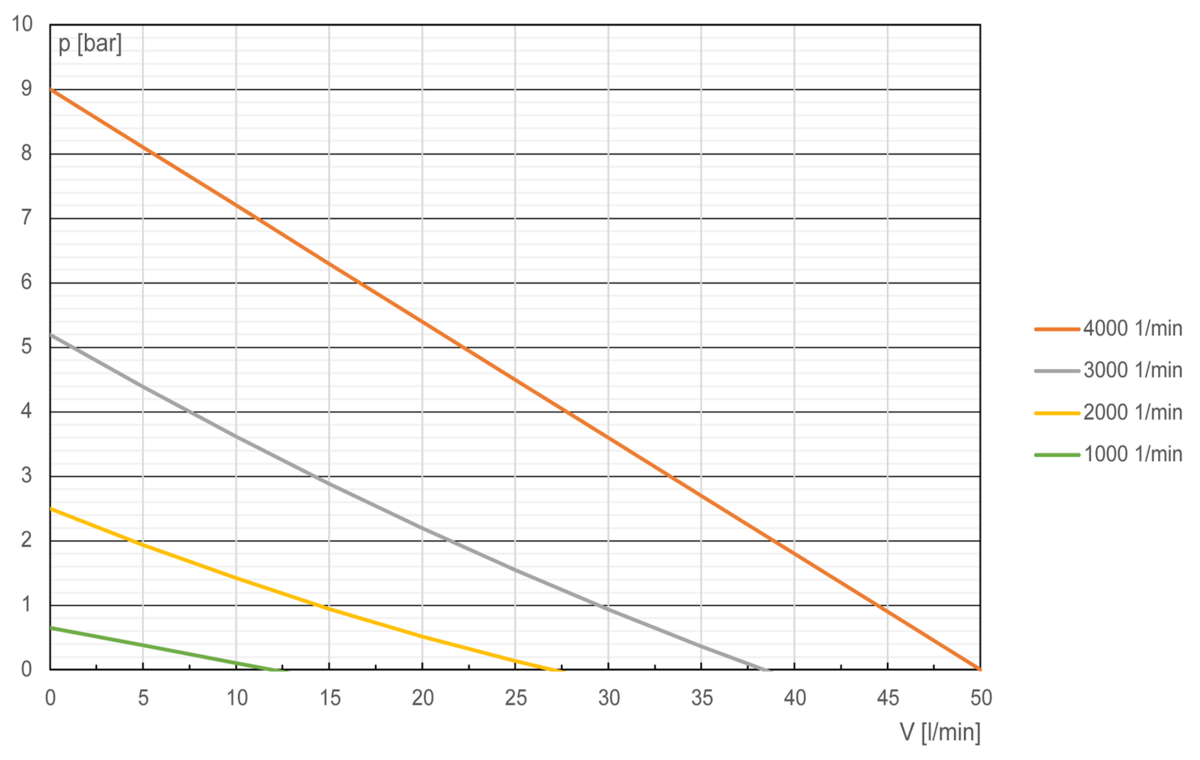

| Pump capacity/Type | PM23H | |

| Flow rate max. | l/min | 50 |

| Power consumption | kW | 1.4 |

| Pressure max. | bar | 9.0 |

| Control system | RT200 | |

| Measuring mode (standard) | Pt100 | |

| Operating voltage | V/Hz | 400/ 50/60 |

| Connections | ||

| Outlet/Inlet | G1/2" | |

| Cooling water mains | G1/2" | |

| Degree of protection | IP54 | |

| Dimensions W/H/D | mm | 235/594/812 |

| Weight | kg | 50 |

| Color | Regloplas green/9005 | |

| Ambient temperature | ||

| max. | °C | 40 |

| Noise level | db (A) | < 70 |

Standard equipment

more

less

- Solid-state relay (SSR) instead of heating contactor

- Filter in the main circuit

- Automatic water refill

- Leak-free pump with magnetic coupling

- Low-scaling and variable cooling system

- Direct access to control system via web-browser (HTML 5)

- Online software-update

- Unit in IP54 protection degree

- RT200 control system

- Timer (Timer function)

- Delta-T control

- Pressure control

- Flow control

- Connection cable 4m for backside unit

- Cascade control Inlet Sn3

- Flushing of unit

- Set point value ramp

- Draining the consumer by suction

- Vapor suppression

- Outlet pressure on Display

- Pump condition monitoring

- Interface OPC UA RT200 (WLAN/Ethernet)

- Ethernet RJ45 Service Interface

- One additional interface of your choice

- USB data logger

Pump curve

more

less

Cooling curve

more

less