Products

Process reliability and efficiency in temperature control

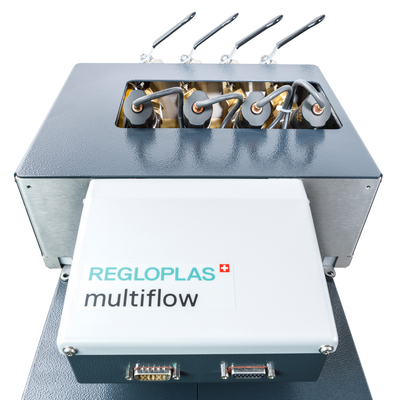

REGLOPLAS is the leading provider of intelligent solutions for temperature control, with an extensive portfolio of temperature control units, temperature control solutions and cooling units.

Our products and systems enable precise and efficient processes for equipment and manufacturing methods in the fields of injection molding, die casting, extrusion, composites, food production, semiconductor and electronics manufacturing, test equipment, and other advanced manufacturing processes. Our solutions enable technological advancement in the automotive, aerospace, plastics, rubber, electronics, pharmaceutical, chemical, medical, food and packaging markets.